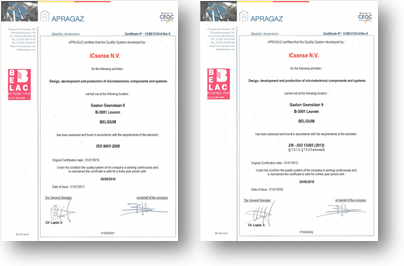

ICsense is certified to ISO 9001:2015 and ISO 13485:2016 for the “Design, development, and production of microelectronic components and systems”. The company’s Quality Management System (QMS) is a cornerstone of its operations, ensuring that all processes are rigorously defined, consistently applied, continuously improved and checked for their effectiveness. ICsense’s QMS reflects a deep commitment to quality, compliance, and operational excellence, enabling the company to deliver high-reliability ASICs that meet the most demanding industry requirements.

The QMS encompasses a comprehensive, formalized framework that governs every aspect of the organization—from initial business opportunity to volume production and supporting functions. The development lifecycle follows a structured, gated process, with clearly defined milestones, formal reviews, and executive-level approvals at each stage.

Key operational domains such as project management, document control, change management, requirements engineering, and risk management are all meticulously documented and aligned with international standards, including ISO 9001, ISO 13485, IEC 61508, ISO 26262, and IATF 16949 (formerly ISO/TS 16949), incorporating APQP methodologies. For automotive ASICs, Production Part Approval Process (PPAP) is performed to meet the stringent quality and reliability expectations of the automotive industry.

This project flow is embedded in the unique ICsense design environment through checklists, automated report generation and specification tracking. Version control software is used throughout the flow for documents, specifications and Cadence/Synopsys database. Issue tracking software is employed for all company processes.

ICsense’s development process is fully aligned with the requirements of IEC 61508 and ISO 26262, supporting safety integrity levels up to SIL 3 and ASIL C/D. The process is designed to meet the expectations of Part 2 (Management of Functional Safety), Part 4 (Product Development: System Level), and Part 8 (Supporting Processes) of ISO 26262.

A dedicated safety plan is created for each project, including:

• Development Interface Agreements (DIA) with customers and suppliers

• Definition of safety-related work products

• Formal safety reviews and confirmation reviews at key milestones

• Robust configuration and change management processes

Safety analysis is performed using FMEA and FMEDA, addressing both systematic and random hardware failures. These analyses support Part 5 (Product Development: Hardware Level) and are integrated into the overall risk management strategy.

Requirements management is embedded throughout the ASIC lifecycle, ensuring traceability of both functional and safety-related requirements. Special attention is given to the tracking of risk and safety issues, in line with Part 8. For supporting processes, ICsense performs tool qualification according to ISO 26262-8, ensuring confidence in the software tools used for development and verification.

In automotive projects, ICsense supports PPAP (Production Part Approval Process) for product release and provides all necessary documentation for the Safety Manual, enabling seamless integration into the final system’s safety case.

A zero defect strategy is realized by a systematic development, test, qualification and production outlier screening approach. Every step in the development and production process is tailored to ensure a high quality and reliability of the ASICs delivered:

A systematic design and verification process is embedded in ICsense’s design environment, including full PVT simulations (6σ), monte carlo, SOA checks, … to maximise the yield and design robustness.

ASICs typically are designed to cope with harsh environments, incl. following requirements:

ASIC developments are carried out following APQP (project management) and PPAP (approval process) according to ISO/TS16949 for automotive applications.

The testability for both the quality (yield) and reliability (ppm level) requirements of the analog and digital (sub-) blocks is considered from the early stage of the ASIC development . This enables informed trade-off between test coverage, reliability and cost early in the process.

ATPG patterns with high test coverage levels (including bridging patterns, transitional patterns, …) are implemented to ensure high quality levels. Optimisation of test time while maintaining test coverage by integrating dedicated test circuits based on our vast experience with in-house production test

Dedicated qualification is carried out depending on the end application and the ASIC mission profile:

• JESD-47 (industrial)

• AEC-Q100 (automotive)

• Custom qualification for e.g. medical applications

• Specific EMC, ISO pulses and ESD/LU reliability tests are carried out for ASICs operated in harsh environments.

An industrialisation including pre-production lots and a corner/skew lot is carried out before safe launch to demonstrate the manufacturability and robustness of the production ASICs.

Automotive qualified processes with a long longevity and tightened quality monitoring and control are selected for automotive ASICs. Optionally, a (limited) burn in is carried out during safe launch, depending on the end application and customer requirement.

During production defect screening (Vstress, Iddq, …) and outlier detection (PAT, SBIN, …) tests are done to ensure a high reliability (i.e. ppm level quality levels).

RMA, failure analysis and 8D reporting are carried out for any issues detected during/after production.

“Zero-defect is in our DNA. At ICsense, it’s how we design, verify, and deliver quality with confidence.”

Carolien Hermans, Quality Manager